Table of Contents

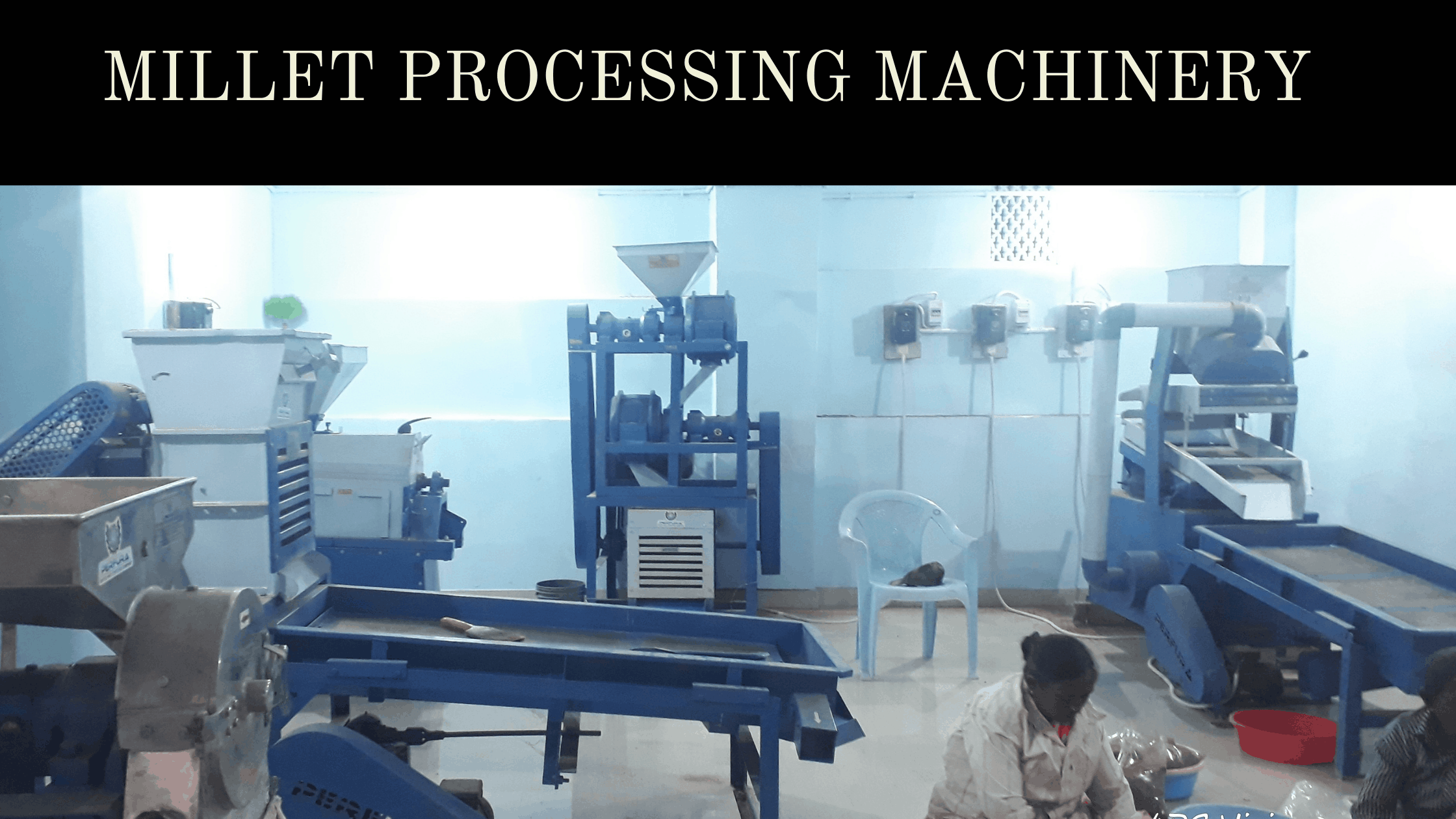

Millet Processing Machinery:

We know that Millets are superior in nutritional properties including high micronutrients and dietary fiber and low glycemic index but to increase the consumption we require the right millet processing machinery. Increasing consumption of millets in India will address the prevalence of the triple burden of malnutrition and increasing non-communicable diseases.

Manual processing of millets involves lot of drudgery and also consumes lot of time. A woman of Bhanjapadar Village of Dasamantpur Block of Koraput said, it takes about one hour to process one kilogram of Little Millet and its real. To know the traditional millet processing I went to a village to document the entire process starting from cleaning of the grains to dehulling. Let us see the video which I have documented for you.

Understanding Millets:

Millets are categorized into two major categories in terms of husk present on the grains (Husked Grains and Naked Grains). There are nine types of millets grown in India. Sorghum(Jowar), Pearl Millet(Bajra), and Finger Millet(Ragi) come under naked millet grains whereas the rest of the millets like Foxtail Millet, Little Millet, Barnyard Millet, Proso Millet, Kodo Millet, and Browntop Millet comes under husked millet grains and these grains require dehulling for consumption.

Challenges in Small Millet Processing:

- The presence of sand particles, small stones, muds balls, and other inert impurities in the millet grains lot increases the duration of the processing, reduces the life of the machines, inferior quality millet product, and also gains lesser price in the market.

- Pest Infestation in the grains decreases the shelf life of millet rice.

- The presence of high moisture in the grains makes them difficult to process and the rice recovery goes down.

- Variations in the millet grain sizes require skilled machine operators.

Millet Processing Machinery required for Setting up a Unit:

To set up a primary millet processing unit, we require machines for cleaning, grading, dehulling, and making value-added products. Let us discuss one by one of each machine.

Grader-cum-Aspirator:

Primary cleaning is done using a grader cum aspirator with the support of different sieve sizes for different millet grains. Grader separates the millet grains from sand particles, stones, sticks, mud balls, sticks, straws, etc. So selecting the right kind of sieve is an important factor to get good quality millet grains.

Before putting the millet grains into the machine, the moisture of the grains should be checked. It should be around 11-12% moisture level. Otherwise, we need to dry the grains in sunlight for 2-3 days for desired moisture level.

Proper care should be taken to prevent the millet grains from clogging. The machine operator can use a brush to remove the grains which are clogged into the sieve. For small millet processing, we generally use a triple deck grader with three sieves.

The top sieve will separate big stones, sticks, straws, etc. which are bigger than the millet grain. The middle sieve will separate the good quality grains and the last sieve will separate the fine and coarse sand particles.

The aspirator attached to the grader will send the fine dust particles to the rear end.

Destoner:

The material coming from the grader is sent to the Destoner for removing the small stones and mud balls that are identical to the size of the grains. Destoner works on the principle of gravity. A Destoner has two sieves under the hopper which grade the material coming from the hopper. The graded material falls on the destoner bed where the lighter material moves towards the front and the heavier material moves towards the rear end.

The air adjustment slot has to be adjusted carefully depending upon the material.

Dehuller-cum-Aspirator:

The raw materials after proper cleaning are sent for husk removal into the huller. Dehullers can be classified into two types under the millet processing machinery.

Centrifugal Dehullers:

A Centrifugal Dehuller has an impeller that is responsible for the husk removal. The material is sent to the hopper which then enters the impeller, where it gets thrown with a great centrifugal force onto the impeller casing. Due to the heavy impact, the husk gets separated from the millet rice and is sent to the aspirator where the lighter husk is collected at the back and the rice is collected at the front.

The quality of the dehuller is measured depending on the retention of the bran layer on the millet rice after dehulling.

Abrasive Dehuller:

Abrasive dehuller is classified into two types, one is the Emery type and the other one is the Rubber roller type. In Emery type dehuller two grinding stones are used for husk removal, where one stone is stationary and the other rotates at a constant speed. The raw material passes through these two grinding stones and the husk gets sheared or abrased off.

In the Rubber roller type, rubber rollers are used instead of stones.

For a better understanding of the Millet Processing Machinery, you can give a look at these videos.

Millet Processing Machinery Layout & Design:

Millet Processing Machine Manufacturers in India:

- Perfura Technologies (India) Pvt. Ltd

- Small Millet Foundation (Division of DHAN Foundation)

- AVM Engineering Industries

- Agromech Engineers

- KMS Industries

- Borne Technologies Private Ltd.

Small Millet Foundation (Division of DHAN Foundation) developed a millet processing machine that can be set on the tabletop. It is said to be India’s First Table Top Dehuller.

Conclusion:

Millet Processing Machinery is making the work easier and thus increasing the consumption of millets. Technology has improved the supply chain of millets. In the coming days, we must focus on decentralized millet processing units in rural areas so that they can reduce the drudgery of women and improve the consumption of millets.

we need a small millet husking machine. please send a quotation

Very good information provide by this article….

Very much thanks….

Plz send quetetion sir